ISO 9001 shows that your quality management system is controlled. ISO 17025 vs ISO 9001 is really a choice between process consistency and defensible measurement results. This guide breaks down scope, outputs, audit depth, and the evidence trail so you can pick the right anchor and avoid duplicate systems.

- If you are a testing or calibration lab issuing results that customers rely on, choose ISO/IEC 17025.

- If you are a non-lab organisation needing consistent processes, choose ISO 9001.

- If you are both: build one system, then layer lab technical controls.

Quick Decision

Start with what you deliver. That output decides which standard carries the weight.

If your lab issues results that customers use for acceptance, compliance, release, or dispute defense, ISO/IEC 17025 is the right anchor. If you primarily need consistent processes, supplier confidence, and organisation-wide control, ISO 9001 is the right anchor.

A clean way to decide is to match the standard to the risk you must control.

- If the risk is “our process is inconsistent,” ISO 9001 is the backbone.

- If the risk is “our measurement is questioned,” ISO/IEC 17025 is the backbone.

- If both risks exist, build one system, then layer lab technical controls.

That decision prevents the most common failure mode, which is duplicate documents with weak evidence behind the results.

Option A vs Option B

Option A: Build around ISO 9001 first

Choose this when your biggest failure mode is inconsistent delivery across departments, and lab results are not used as technical proof near limits.

Option B: Build around ISO/IEC 17025 first

Choose this when your biggest failure mode is disputed measurement, customer complaints on results, or acceptance decisions that depend on uncertainty and traceability.

Trust Anchors

ISO’s annual survey reports 1,265,216 valid ISO 9001:2015 certificates covering 1,666,172 sites for 2022. ISO

ILAC reports over 114,600 laboratories accredited by ILAC MRA Signatories in 2024. (ILAC – ILAC Live Site)

What Each Standard Proves

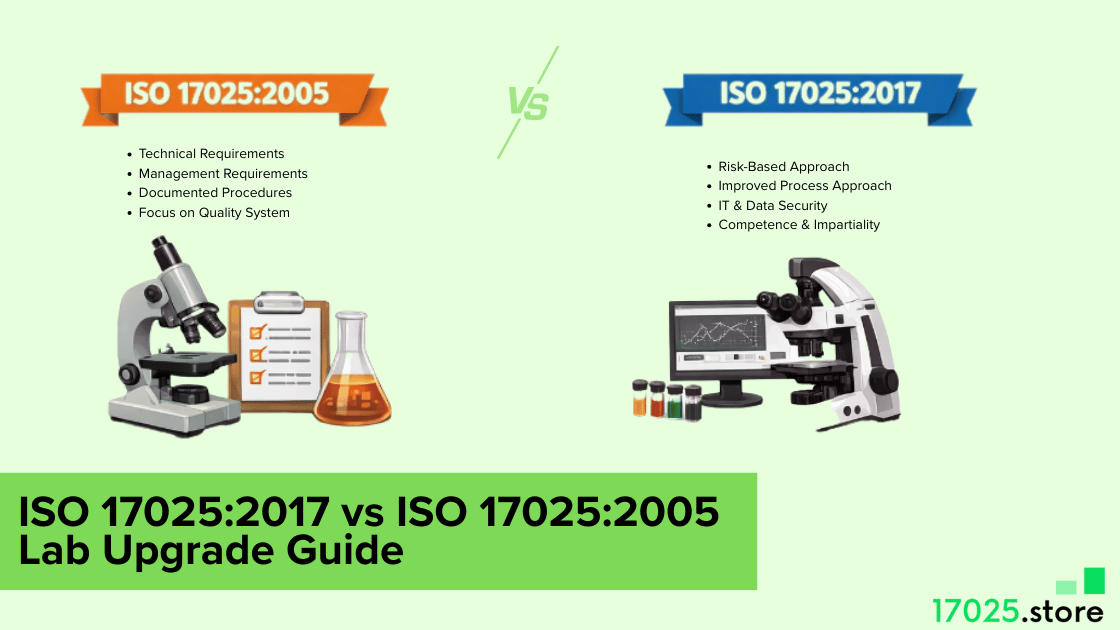

ISO 9001 proves that an organisation runs a controlled quality management system. It is designed to make work repeatable, measurable, and improvable. You get stronger process discipline, clearer responsibility, and better control of nonconformities across departments.

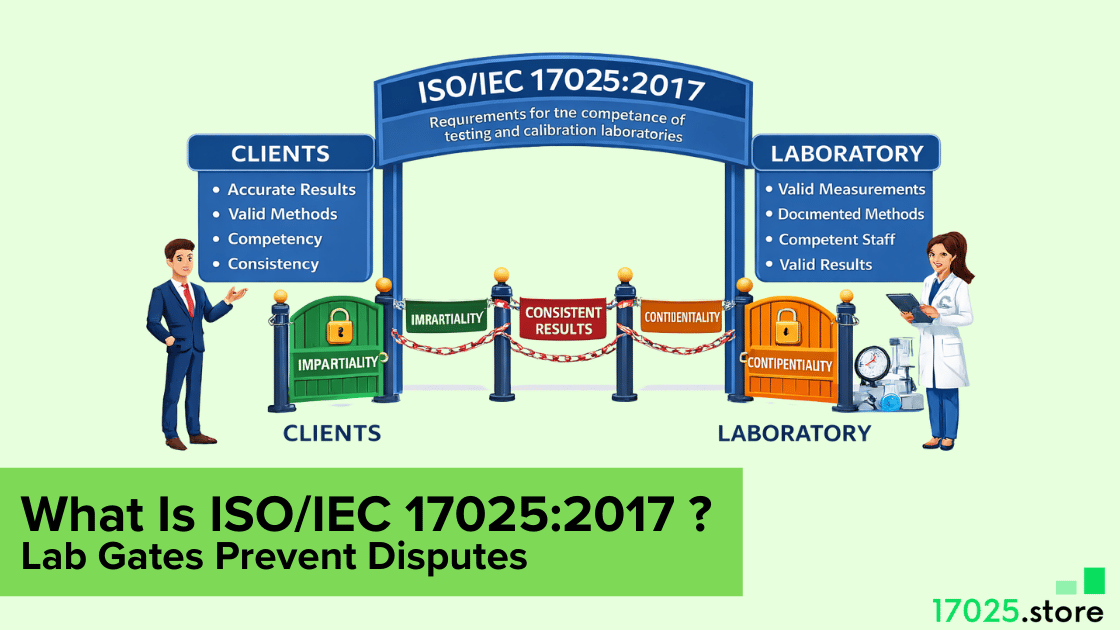

ISO/IEC 17025 proves that a laboratory can produce valid results for defined activities. The difference is not the paperwork volume. The difference is the technical defensibility of a result.

That defensibility is built from method control, competence, equipment control, metrological traceability, measurement uncertainty, where applicable, technical records, and validity monitoring.

A simple way to remember the boundary is this: ISO 9001 improves how you run work. ISO/IEC 17025 improves how you defend results.

Certification And Accreditation

ISO 9001 is typically evaluated through certification audits. The audit checks whether your management system meets the requirements and whether you follow your own controls consistently.

ISO/IEC 17025 is typically evaluated through accreditation assessments, where competence is judged against your scope. The assessment does not stop at procedure statements. It drills into method use, records, calculations, and how the lab controls validity over time.

That difference is why ISO 9001 can feel “system-heavy,” while ISO/IEC 17025 feels “evidence-heavy.” Labs often underestimate this gap and only realise it during a technical witness or a deep dive into records.

How To State Compliance Correctly

ISO 9001: Certified (your management system meets requirements and is consistently controlled).

ISO/IEC 17025: Accredited (your technical competence is proven to a defined scope of tests/calibrations).

If your market language blurs these two, you attract avoidable disputes. Customers interpret “certified” and “accredited” very differently when a result is challenged.

Where ISO 9001 Maps Into ISO/IEC 17025

This is not a one-to-one clause match. It is a practical alignment, so you reuse what matters without weakening lab evidence.

| ISO 9001 theme | Where it lands in ISO/IEC 17025 | What to carry over (without dilution) |

| Process control and documented information | Clause 8 (Management system) | Document control, change control, internal audits, and management review |

| Competence and training | Clause 6 (Resources) | Competence criteria, authorisation, training effectiveness evidence |

| Equipment and calibration control | Clause 6 + Clause 7 | Equipment control that closes the traceability chain |

| Nonconformity and corrective action | Clause 8.7 | Root cause, correction, and effectiveness check tied to the result risk |

| Monitoring, measurement, improvement | Clause 7 + Clause 8.6 | Validity monitoring signals, trend reviews, and improvement actions |

ISO 17025 vs ISO 9001 Comparison Table

| Decision Point | ISO 9001 emphasis | ISO/IEC 17025 emphasis | What it means in practice |

| Scope | Organisation-wide QMS | Defined lab scope | Your scope must match outputs |

| Promise | Process consistency | Result validity | Results must be defensible |

| Recognition | Certification | Accreditation | Competence is assessed in scope |

| Methods | Controlled processes | Method suitability | Method control drives credibility |

| Traceability | Calibration control | Metrological traceability | The traceability chain must close |

| Uncertainty | Not central | Core where applicable | Decisions must reflect uncertainty |

| Technical records | Controlled records | Technical records | Another person can recreate the result |

| Validity monitoring | KPI reviews | Validity monitoring | Drift detection becomes mandatory thinking |

Evidence That Makes Results Defensible

Most weak implementations fail in the same place. The system looks fine, but the evidence behind the results is thin. ISO/IEC 17025 demands a technical evidence trail that can reproduce a reported result without guesswork.

A lab-ready evidence trail has three layers that must align.

Layer one is management control. Layer two is technical control. Layer three is result defense. When these layers disagree, audits become painful, and customer confidence drops fast.

The most important evidence to get right is predictable.

- Technical records that recreate the full result path.

- Metrological traceability proof that closes without gaps.

- Measurement uncertainty logic tied to decision impact.

- Validity monitoring that catches drift early.

- Reporting controls that prevent silent template errors.

Once these are stable, the rest of the system stops feeling heavy. Work becomes calmer because every output can be defended.

What Assessors Actually Test

Measurement uncertainty is not a mathematical ornament. It is a decision input. If your acceptance limit is tight, uncertainty changes the risk of a wrong accept or a wrong reject. That is why strong labs link uncertainty to decision rules rather than keeping it as a standalone calculation.

Micro-example:

A customer uses a calibration certificate to accept a gauge near a spec limit. Your measured value is barely inside tolerance, but the stated uncertainty overlaps the limit.

If your report makes a “pass” claim without a clear decision rule, you have created a dispute risk. A good ISO/IEC 17025 system forces you to show how uncertainty impacts conformity at the limit, and what rule you used to make the claim.

Metrological traceability is not “we calibrated the instrument.” Traceability is a documented chain that connects your measurement to reference standards with known uncertainty at each step. Break the chain, and the result becomes an opinion.

Validity monitoring is not “we do internal QC sometimes.” Validity monitoring is planned evidence that your method stays in control over time. Control samples, intermediate checks, replicate trends, or proficiency comparisons are typical tools, but the key is the logic: detect drift before customers do.

Audit Differences ISO 17025 vs ISO 9001

ISO 9001 audits usually confirm system conformance and consistency. Sampling focuses on whether processes are followed, records exist, actions are closed, and improvement cycles run.

ISO/IEC 17025 assessments and audits go further into technical proof. A single issued result can trigger a deep record trail review, including raw data integrity, calculation correctness, equipment suitability on the day, environmental suitability, method usage, traceability chain, and uncertainty decision impact.

This is where the “ISO 17025 audit” behaves differently than people expect. The assessor is not only checking that you have a system. The assessor is checking that your reported result is defensible.

An “ISO 17025 internal audit” should mirror that reality. The strongest internal audits are report-trail audits. One report is selected, then every critical statement is traced back to objective evidence, and then forward again to the issued decision. This turns internal audit into a competence test, not a paperwork review.

Result Defensibility Stress Test

Most competitor pages do not give you a sharp self-check. Use this test on any single report or certificate before you trust it.

Ask five questions.

- Can another competent person recreate the result from technical records alone?

- Can you show a complete metrological traceability chain for the critical measurement?

- Would measurement uncertainty change the accept or reject decision at the limit?

- Was the method suitable for the sample and range used that day?

- Do you have validity monitoring evidence that drift is controlled?

A “no” to any one question is not a small gap. It is a credibility gap.

FAQ

1. Is ISO 17025 the same as ISO 9001?

No. ISO 9001 is a general quality management system standard. ISO/IEC 17025 is a laboratory competence standard tied to the technical validity of results.

2. Do labs need ISO 9001 before ISO/IEC 17025?

No. ISO 9001 can strengthen management controls, but ISO/IEC 17025 stands on its own when your goal is defensible lab results.

3. What is accreditation compared to certification?

Certification confirms a management system meets requirements. Accreditation evaluates technical competence to a defined scope.

4. What does ISO/IEC 17025 check that ISO 9001 does not?

It checks the technical validity behind results, including traceability, uncertainty impact, technical records, method control, and ongoing validity monitoring.

5. Which is better for a lab: ISO 17025 vs ISO 9001?

Choose ISO/IEC 17025 when customers rely on your measurement results. Choose ISO 9001 when you need organisation-wide process consistency. Use both only when you control duplication by design.

Conclusion

ISO 9001 and ISO/IEC 17025 solve different failure modes. ISO 9001 stabilises how work is run across an organisation. ISO/IEC 17025 stabilises whether a reported result can be defended under technical scrutiny.

The decision becomes clear when you look at outputs. If your customers depend on your test report or calibration certificate, you need the evidence depth that ISO/IEC 17025 enforces.

If your core risk is inconsistent processes, ISO 9001 gives the control structure. When both risks exist, one integrated system with a strong technical evidence trail beats two parallel systems every time.